2024-01-15 Certainly! Here's a guide for CNC machining of alloy steel, covering material model selection, machining methods, surface treatment methods, and transportation considerations:Alloy Steel CNC Machining Guide:1. Material Model Selection:1.1 Alloy Steel Overview:Alloy steel is a versatile material know

Read More

2024-01-11 Materials Overview:Mild steel is a low-carbon steel alloy known for its strength, ductility, and affordability.Grades like AISI 1018 and AISI 1020 are common choices for CNC machining due to their ease of machining.Tool Selection:Carbide tools are preferred for mild steel due to their hardness and w

Read More

2024-01-08 Stainless steel CNC machining is a crucial aspect of manufacturing high-quality components with precision and durability. This guide delves into key steps, including material model selection, machining methods, surface treatment options, and transportation considerations, providing valuable insights

Read More

2024-01-04 Aluminum alloy CNC machining plays a pivotal role in various industries, providing a versatile and efficient method for manufacturing high-quality components. In this comprehensive guide, we will delve into key aspects of aluminum alloy CNC machining, including model selection, machining methods, su

Read More

2024-01-02 Material Model Selection:Choose high-quality tool steel materials based on specific application requirements.Common tool steel grades include D2, A2, M2, and O1, each offering unique properties. Applicable Industries:Widely used in the aerospace, automotive, and tooling industries.Tool steel is esse

Read More

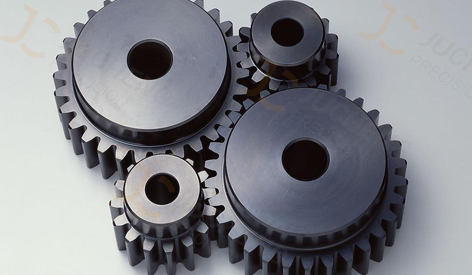

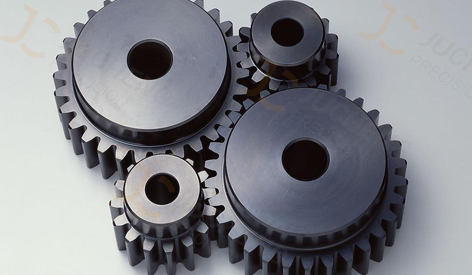

2023-12-28 Creating prototypes for housing and gearboxes parts involves careful planning and execution to ensure the functionality, durability, and compatibility of these critical components. Here is a guide for prototyping housing and gearboxes parts: Define Objectives:Clearly outline the purpose and function

Read More

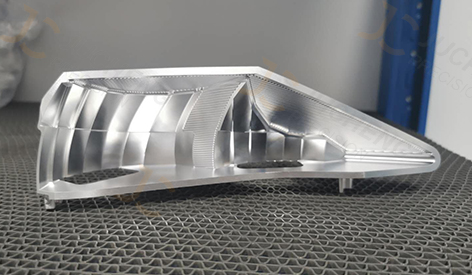

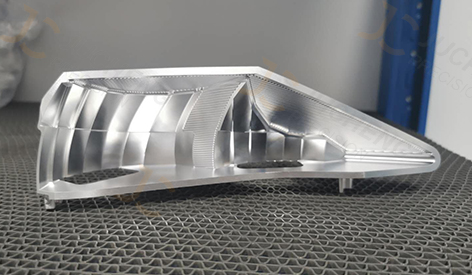

2023-12-26 Creating automotive lighting prototypes is a crucial step in the development of vehicle lighting systems. Here is a guide for manufacturing automotive lighting prototypes: Define Objectives:Clearly outline the purpose of the automotive lighting prototype.Identify key features, specifications, and re

Read More

2023-12-20 Creating a plastic housing prototype for a medical device is a crucial step in the product development process. It allows for testing the design, functionality, and user experience before moving on to mass production. Here's a guide for prototyping the plastic housing of a medical device:1. Define O

Read More

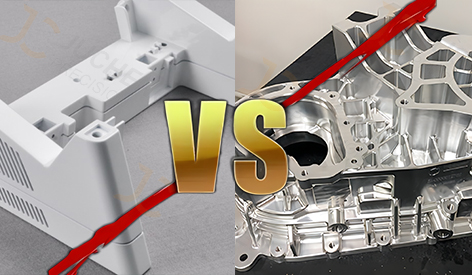

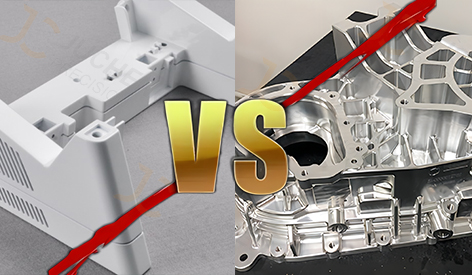

2023-12-18 Metal Prototype VS Plastic Prototype Guide: Material Characteristics: Metal Prototype: Typically made of materials like aluminum, steel, or alloys. Known for strength, durability, and resistance to high temperatures.Plastic Prototype: Uses materials such as ABS, polypropylene, or polycarbonate. Offe

Read More

2023-12-13 Reaction Injection Molding (RIM) Part Manufacturing Guide:1. Introduction to Reaction Injection Molding:Definition: RIM is a low-pressure molding process combining liquid components to produce high-strength, complex parts.Advantages: Cost-effective for large, intricate components with excellent surf

Read More